By Russtum G. Pelima

KIAMBA, Sarangani (March 5, 2009) – Valued by its first Christian settlers more than half a century ago, this town’s rich soil not only grows cultivated crops but also abounds with abaca (Musa textilis), aspecies of banana native to the Philippines.

Now, many of its highlanders live out of it.They are the Tboli “sinamay” makers of the United Maligang Farmers Multi-Purpose Cooperative (UMFMPC) in Maligang, some four kilometers from the town’s highway.

By now, there are at least 15 of them trained by the Department of Trade and Industry (DTI) and the Fiber Industries DevelopmentAuthority (FIDA), and provided equipment by the Department of Laborand Employment (DOLE) and the municipal government.

Twenty-five women form barangay Badtasan, with four from UMFMPC,finished the February 17-18 training on fiber treating and dyeing.

For the “sinamay” project, the DTI has provided three loom-weavingequipment. DOLE provided a working capital and eight looms for thecoop.

It is remarkable how the “sinamay” makers preserve a tradition of perseverance and animistic faith in giving value to the plant aside from making business out of it.“Sinamay making is sacred,” Eliza Cango said. Eliza is one of the“sinamay” makers who have depended on it for her family of ninechildren. She believes by doing so, she was preserving an oldtradition of her tribe.“We pray every time we start making a piece of sinamay. We pray beforeinserting the first three very fine fiber threads into the sulod,” she disclosed.“We pray to the tree, the wind, the soil the water, to guide us inmaking a beautiful sinamay and give us a bountiful harvest.”

“Sinamay” is a product of laboriously and painstakingly weaving the“tinagak” which comes from the “eskuhido”.“Eskuhido” or the raw fiber threads are stripped strands of leaf sheath from the abaca trunk by the use of a stripping machine or by bare hands. “Eskuhido”, sold by kilo, is produced and marketed easilyand often results to market surplus.“Tinagak” is a finely knotted abaca filament or fiber thread. A bunchof it, about three meters long, is rubbed hardly by bare hands tosoften the strands and then combed to remove the broken ones. A bunchof it, commonly in three meters, is then soaked into a pail, boiledand dyed until it is finally ready for “sinamay”.“It really needs a lot of patience and perseverance,” Eliza said.First, the “tinagak” is inserted into a combed-like “sulod” in amachine called handloom. It is then woven using a wooden orbamboo-made “baruto” using the maker’s two hands while pedaling totighten the threads to make up a “sinamay” cloth.

At P45 per meter, a “sinamay” maker has to spend a day to finish one,“but it’s really worth the effort seeing the finished product in themarket” Eliza mused.Glittered “sinamay” cloth makes an elegant packaging material. It canalso be dyed and colored for hat adornment or ribbon for wine bottles.Other natural fiber-made products from “sinamay” common in the market today are basketries, sandals, hats, slippers and bags.

The UMFMPC in four-year time has grown into a business under the Small and Medium Enterprise (SME). Members farm their own abaca.

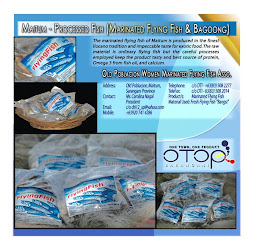

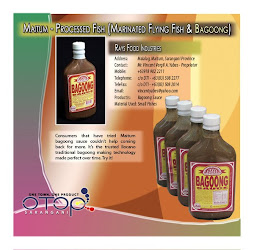

Ricardo Malayo, the coop’s vice chairman said they can produce 10,000meters of “sinamay” monthly from their harvest as required by the Peral Enterprises in Manila which they had signed a memorandum of understanding with last year.“Eventually a marketing agreement would be forged with Cystal Seas,”said Engr. Nenita Barroso, DTI provincial director. “The projectoffers employment opportunity and income to women and uplandcommunity.”Crystal Seas of Davao and UMFMPC have ventured intotechnology-production and product development. Crystal Seas has alsoplaced orders for “sinamay” and dyed twines, Barroso said.As other barangays, Lomuyon, Tambilil, Tamadang, Falel and Tablao,also produce abaca, DTI has declared it Kiamba’s One Town One Product(OTOP).

At the province’s MunaTo Festival last year, Kiamba won the best booth among the seven towns exhibiting their OTOP, tourism destinations and investment potentials. The municipal government intends the prize ofP100,000 to assist UMFMPC.

In his State of the Municipality Address on February 10, as the town celebrated its 61st founding anniversary and 5th Timpuyog Festival,Mayor Rom Falgui said a P2.8-million worth of tissue culture laboratory for abaca will soon be constructed with assistance from the Department of Agriculture and the provincial government.Abaca was first cultivated on a large scale in Sumatra in 1925 underthe Dutch who had observed its cultivation in the Philippines for cordage since the 1800s. (Russtum G. Pelima/SARANGANI INFORMATIONOFFICE)

Subscribe to:

Post Comments (Atom)

1 comment:

Hello.. sino po pwede matawagan sa Maligang farmers multi purpose cooperative. At pwede din po ba mahingi ang exact address nila? Gusto ko po makita ang finish products nila. Para may mapagkunan ako na nandito lang sa Mindanao area. Salamat po.

Post a Comment